METAL 3D PRINTING

HELLO FRIENDS!!

INTRODUCTION OF METAL 3D PRINTING

Metal Additive Manufacturing, or 3D printing, offers the possibility to produce complex parts without the design constraints of traditional manufacturing routes:

Metal Additive Manufacturing, also known as metal 3D printing, offers unrivalled design freedom with the ability to manufacture parts from a wide range of materials.

Components that would not have even been possible just a few years ago can now be made to high standards using a wide range of metal powders. No longer solely a prototyping technology, Additive Manufacturing is now being used for the production of series components for the most demanding applications.

Additive Manufacturing, also referred to as 3D Printing, is a technology that produces three-dimensional parts layer by layer from a material, be it polymer or metal based. The method relies on a digital data file being transmitted to a machine that then builds the component.

Methods For 3D Printing Metal:

* Metal binder jetting :

Binder Jetting is an additive manufacturing method that creates parts additively with a binding agent. The process uses a liquid binding agent deposited on the metal powder material, layer by layer, according to your 3D model.

Between each layer, the powder is lightly cured for solidification. When the printing process is complete, the build box is removed from the printer and placed into an oven for curing.

When the process is over, an operator carefully extracts the parts from the build box and removes the remaining powder thanks to brushes and air blowers.

When the process is done, the parts are separated from the runners, cleaned and beadblasted to remove the remaining powder. The part can now be shipped to you or finished according to your choice

.

Binder Jetting technology enables you to 3D print with several types of metal alloys. On our online 3D printing service, you can now order two materials produced with Binder Jetting 3D printers:

We also offer other metal 3D printing online, using DMLS, SLM or metal casting techniques:

- With DMLS: Stainless Steel SS316L and Titanium TiAI64V grade 5

- With SLM: Aluminum AlSi7Mg0,6

- With Metal Casting: Sterling Silver and Brass

Metal Binder Jetting can be used with many different finishing options. If you wish to 3D print a metal project with special requirements or specific platings, you can contact our sales-team.

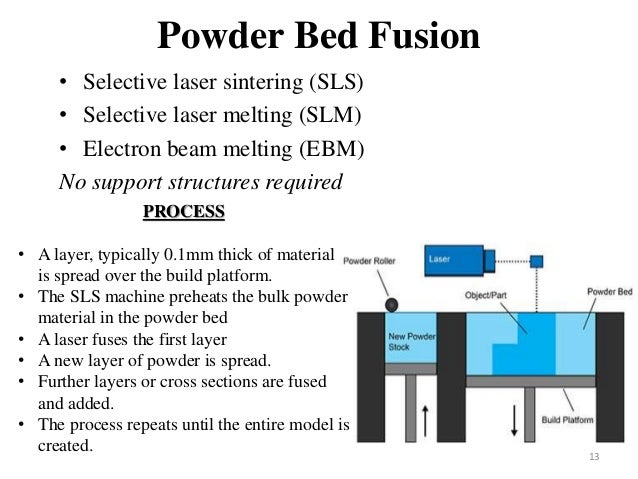

POWDER BED FUSION:

The process of powder bed fusion is very similar to metal binder jetting except instead of a binder being deposited to fuse layers of metal powder together, a high temperature laser or electron beam is used. The laser increases the temperature of the powder in the areas where the design is being built, fusing the metal powder and creating a solid layer.

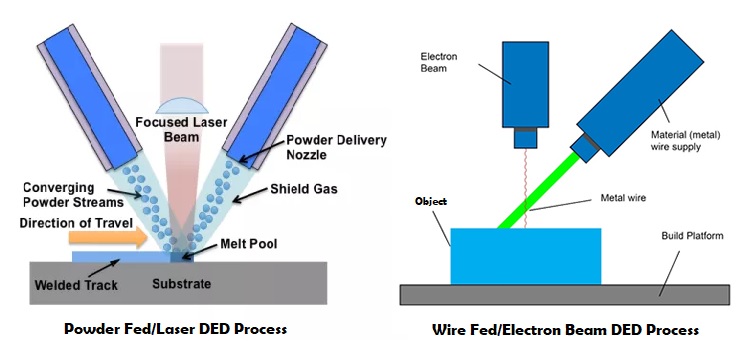

DIRECT ENERGY DEPOSITION:

This process uses two different types of material – metal wire or metal powder. A nozzle that moves in multiple directions (4-5 axis) extrudes metal powder or wire material layer by layer. Once the material is deposited, it is melted with a laser or electron beam. This process continues and the object is built up layer by layer. Although this process is usually used to repair and maintain existing metal material, it can be used to create objects from scratch.

3 STUNNING 3D PRINTS:

1: Bracelet ‘Bricks’ by 3DSVP:

2: Key Chain ‘Mjolnir’ by Little Things:

3: Watch ‘F’ by Pinar Timur:

Post a Comment